Water scarcity has been listed by the World Economic Forum as one of the three global systemic risks of greatest concern.

22% of global water consumption and pollution is due to raw material exports. Mining and processing facilities are highly water-intensive businesses, and water scarcity is affecting the mining industry’s operations. Collecting the wastewater from the processes in the Waste Storage Area and recycling it for reuse in the process is an important step for environmental awareness and sustainability, and significantly reduces the overall fresh water requirement in the facilities.

When the pollutant profiles of wastewater originating from copper processing processes are examined, it is known that they are rich in hardness, sulfate and heavy metal pollution. It is necessary to use sulfate removal processes consisting of several steps in order to bring the wastewater to the discharge standards or to reuse it.

Gold mines are the ones with the highest water consumption per kilogram of metal among the mining industries. Since gold processing takes place in several stages, wastewater has physicochemical properties that vary according to its source.

SETAŞ, is ready to offer solutions for the mining industry with a large blue water footprint, for more rational use of existing water and for the transition from a buy-and-dispose model to a circular economy model.

ACACIA MINING OPERATIONS-TAILINGS STORAGE FACILITY(TSF) YILANLI WASTE WATER TREATMENT-RECOVERY PLANT-9600 m3/day

Treatment of mine wastewater from the past to the present, has a great importance for the continuity and efficiency of the mining sector. The quality of process water is important in the ore enrichment process. Wastewater from the ore enrichment process causes huge volumes of waste storage facilities to be built, thus causing great energy losses and environmental pollution.

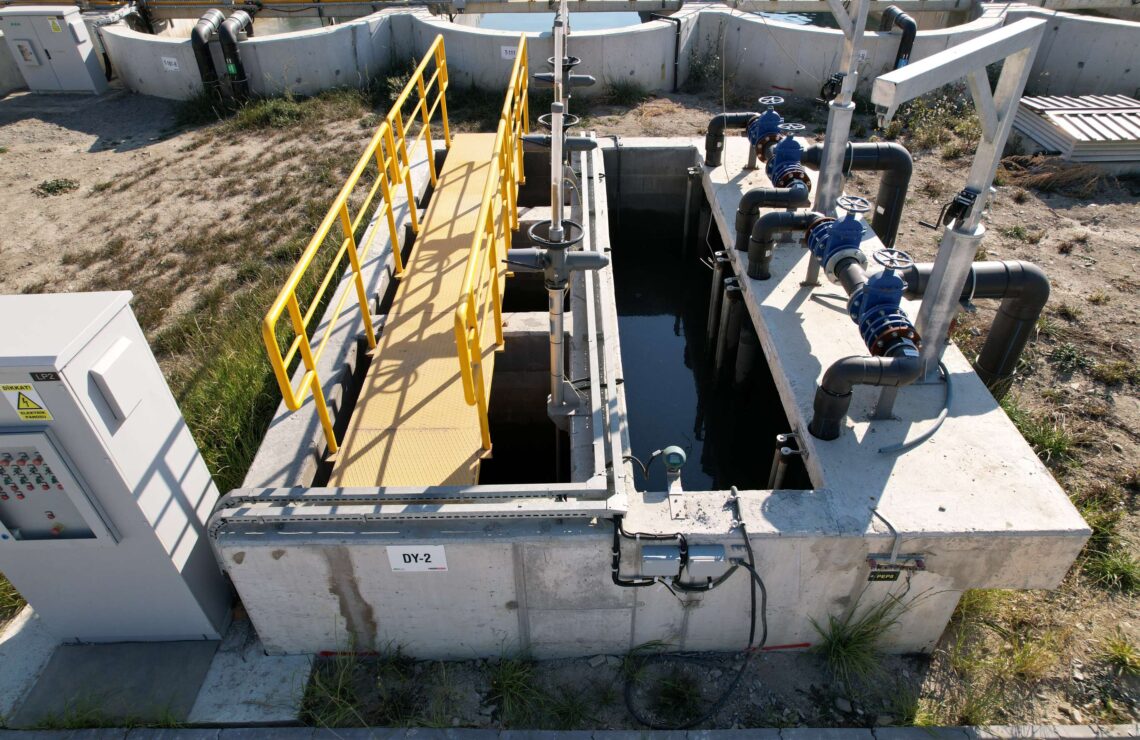

As Setaş, we have engaged the system we designed for the treatment of the wastewater of the Copper Mine Tailing Storage Facility (TSF) and the reuse of the treated water in the process, at Acacia Mining Operations, located in Hanönü, Kastamonu.

At the plant, wastewater from TSF is primarily recycled through physical pre-treatment, chemical treatment, multimedia filters and reverse osmosis membrane treatment units, and used as process water in Acacia Mining Operations.

The plant was engaged with all its units in January 2022 and its temporary acceptance was made as of 01.02.2022. The plant has been operated by Setaş experts since February 2022.

ANAGOLD MINING – ÇOPLER MINING SITE PILOT FACILITY TREATABILITY STUDY

At the gold production facilities of Anagold Mining, located at the Çöpler Gold Site located in İliç, Erzincan, in our portable pilot plant located in the mining production area, recovery research and development studies were carried out for three months.

Quality Product

We offer our customers quality products at international standards.

Customer Satisfaction

We design our work on customer satisfaction.

Eco-Friendly

Our company "Save water, protect the environment!" works with the principle.